BLANK

MOULDING

TECHNOLOGY

AT MOULDED OPTICS,

WE STAND OUT FROM

COMPETITORS BY

OFFERING:

- VERSATILE SOLUTIONS

Moulded Optics specialises in precision glass and polymer

solutions for a range of industries, such as lighting, medical,

automotive, and more.

We provide complete services, from designing optical

components to creating prototypes with cutting-edge

technology (CMM) and high-quality serial manufacturing.

3. EXPERT TEAM

Our skilled and experienced technical team leads

the way in a controlled production environment.

4. PROBLEM SOLVERS

We’re known for our solution-oriented approach to

developing and implementing innovative

optical solutions.

MANUFACTURING

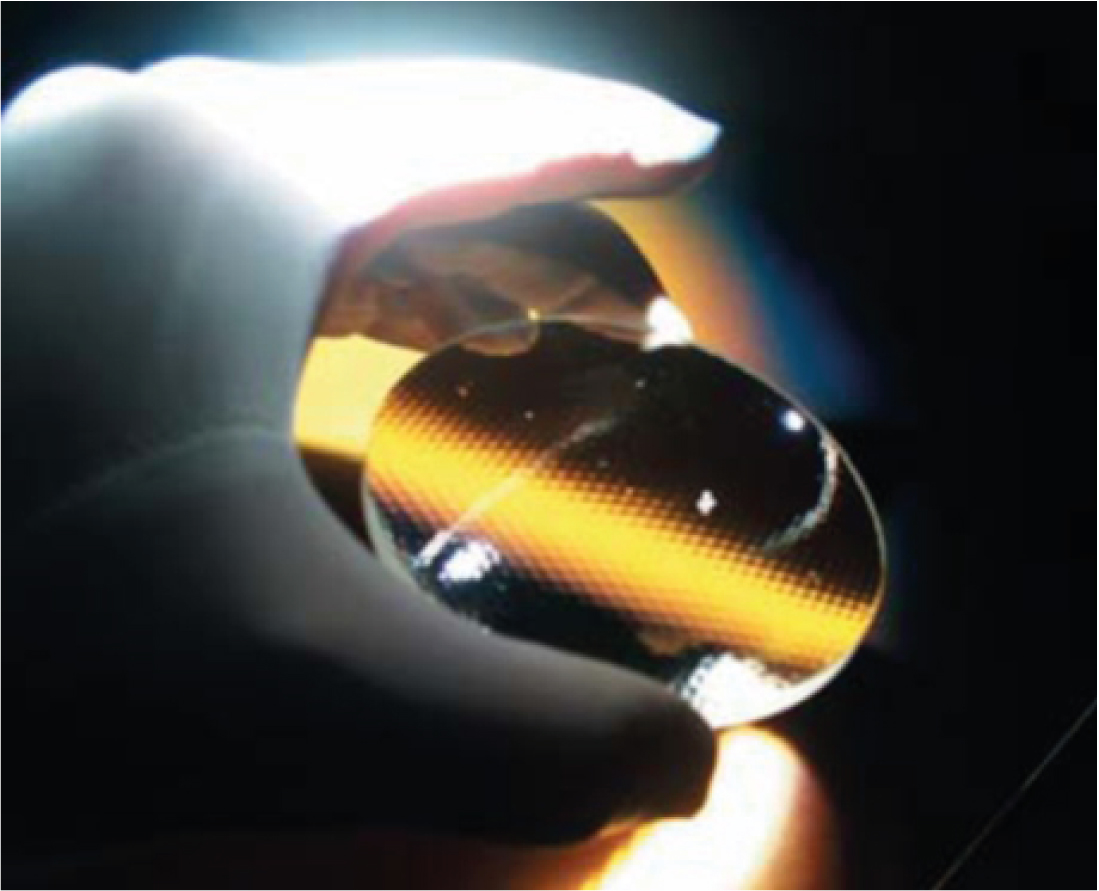

Our advanced blank moulding manufacturing process,

coupled with precise measurement systems at every

stage, ensures the quality expected from a Made-in

Germany production that aligns with our customers’

exacting requirements.

DECADES OF EXPERTISE

With 20+ years of experience, we continually optimise design, moulding, and production,

rigorously checking quality throughout. Our integrated system delivers innovative solutions

quickly, driven by our experienced team leaders within our family-owned structure.

TYPES OF MOULDING

PROCESSES

- ROD MOULDING

TECHNOLOGY

Our experts use rod moulding, which simplifies

production by using one size for various lenses. This

saves costs and offers flexibility in crafting different

shapes and diameters from various glass types.

2. GOB PRESSING

For high-volume precision automotive headlight

optics, we rely on gob pressing. This efficient

technique allows us to produce large quantities with

unmatched precision

MOULDING

We employ creative methods to make compact

optics, including small and hybrid optics, using

materials like PMMA and polycarbonate. This

approach ensures both affordability and

outstanding optical performance

PRODUCING BLANK-MOULDED

OPTICS: A SIMPLE EXPLANATION

- OPTICS DESIGN &

DEVELOPMENT

We start by understanding what our customers need for

their optical products. Then, we come up with solutions that

balance technology and cost-effectiveness to meet

those needs.

Making precise moulds for blank moulding is complex, but we

excel at it. Our experienced engineers use their research skills

to create the right moulds for our clients. Our in-house

moulding and tooling department lets us respond quickly

with creative solutions

3. OPTICS PROCESSING

We handle all the steps in making optical components

ourselves. This includes blocking, grinding, polishing, centring,

edging, and using heat and chemicals to harden them.

4. COATING

To improve the performance of optical parts, we add

special coatings. These coatings are like special layers that

help the optics work better. We have different types, like

mirrors, anti-reflective coatings, and more, tailored to

what our customers need for their projects.

WE OFFER:

High-Reflective-Mirror-Coating

Anti-Reflex-Coating

Front-surface mirror coating

Cold mirror coating

UV Blocker

IR Blocker

Sapphire coating

5. SAPPHIRE COATING

We create sample products that are ready for testing.

These samples are carefully checked by our in-house

Quality Assurance team. We then provide a report,

called the “Initial Sample Report,” to the client.

6. SAMPLING

We create sample products that are ready for testing.

These samples are carefully checked by our in-house

Quality Assurance team. We then provide a report,

called the “Initial Sample Report,” to the client.

QUALITY CONTROL

After we finish making the optics, our dedicated team

carefully checks each one to make sure they are perfect.

This is like a last check to ensure they are very precise and

work well.

8. SERIAL PRODUCTION

We make many of these precision products one after the

other. We are very strict about quality control, and because

of this, our products are consistently precise and high-quality.

QUALITY AT MOULDED OPTICS

At Moulded Optics, we pride ourselves on delivering excellence, backed by our ISO 9001:2015 certification for quality management. Our commitment to quality extends to compliance with industry standards such as ROHS, REACH, and the Conflict Minerals provision of the Dodd-Frank Act, ensuring that our products meet the highest environmental and ethical standards.

But our dedication doesn’t stop there. Our values are deeply rooted in sustainability, social responsibility, and innovation. From utilizing eco-friendly practices and sustainable materials to embracing cutting-edge technology, we strive to not only meet but exceed expectations, delivering products that make a positive impact on both our customers and the world around us.

Our values extend beyond product excellence to include:

Customer Satisfaction: With less than 1% complaints, we prioritize exceptional customer service, a cornerstone of our success.

Trustworthy Quality: Our skilled workforce and advanced equipment ensure consistent, high-quality custom solutions.

Prompt Delivery: Combining traditional methods with modern technology, we deliver quality, competitiveness, and fast turnaround times.

Global Presence: From our European headquarters, we support a diverse global clientele.

Stringent Quality Control: Inspecting 100% of optical surfaces, in 2022 alone, we qualified over 600,000 surfaces, maintaining the highest standards.

Versatile Projects: Whether prototypes or large-scale production, we’re confident in meeting diverse needs and exceeding expectations.

Skilled Human Resources: Our German production site, using blank-moulding technology, boasts dedicated and skilled team members ensuring precision.

Made in Germany: Operating from Schoffengrund since inception, we proudly embody the “MADE IN GERMANY” commitment.

Solution-Oriented Precision: Embracing dedication to precision optics, we design, develop, engineer, and manufacture client-focused optical solutions.

Reduced Lead Times: Our streamlined supply chain and in- house processes significantly shorten production times for most components.